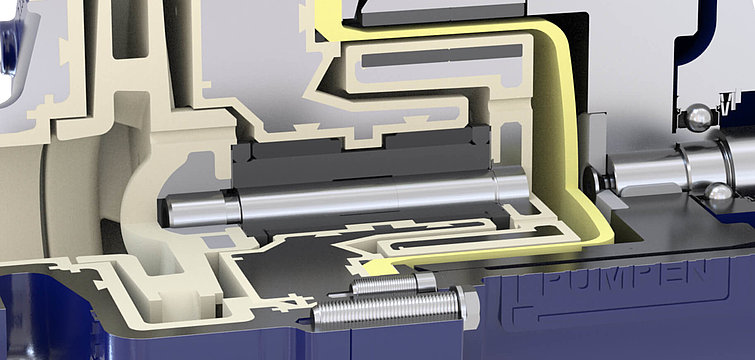

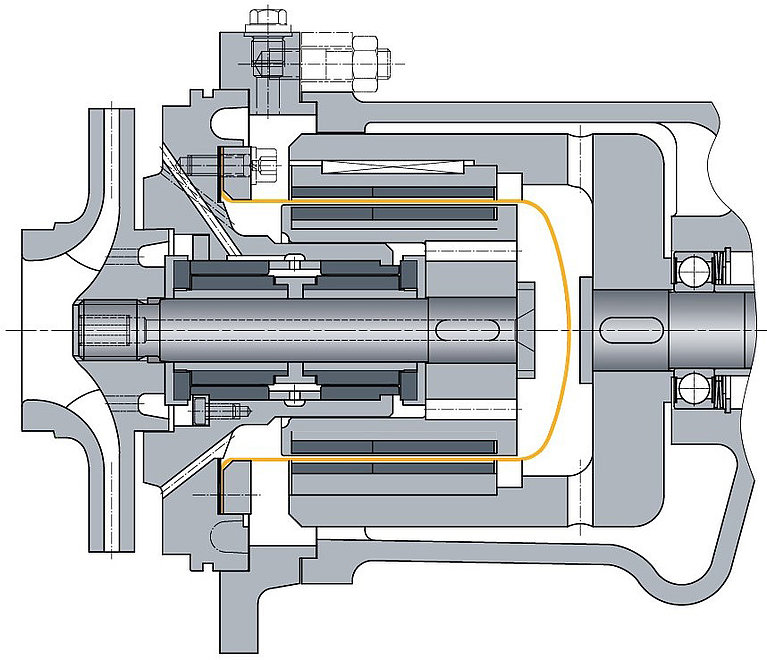

The magnetic coupling is based on a completely different sealing principle. Here the drive for the hydraulic part of the pump takes place through the pairing of permanent magnets whose external unit transmits the torque generated by the motor to an internal unit, which in turn transfers this to the impeller.

The external or atmosphere side magnet system is separated from the internal product side magnetic system by a spacer can made of non-magnetic material. The torque needed to drive the impeller is transmitted exclusively by magnetic forces which act through the spacer can. The pump it is thus hermetically sealed.

The axial and radial mountings for the pump shaft are through hydro-dynamic sleeve bearings made of silicon-free silicon carbide. Bearing lubrication and heat removal normally takes place through the pumped medium, in two separate circuits.