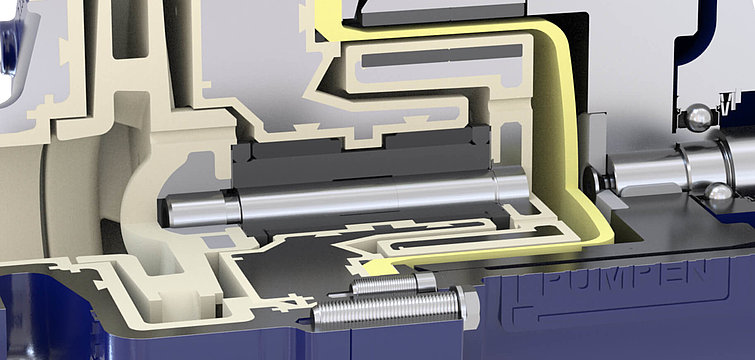

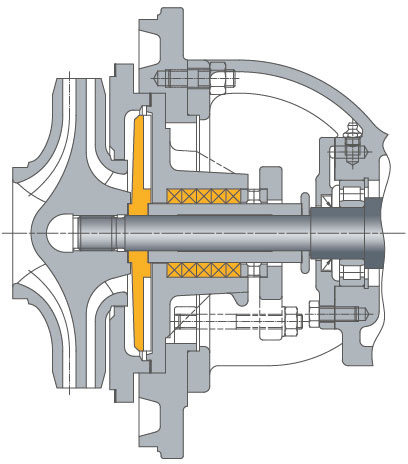

The hydrodynamic shaft seal works without contact and without wearing parts. It requires no maintenance of any sort and is particularly suitable for continuous operation. With the aid of impeller back blades and a downstream auxiliary propeller the shaft gland is completely relieved hydrodynamically from the pump and inlet pressure. The medium is kept away from the shaft gland.

When the pump is operating a liquid ring appears in the auxiliary impeller which isolates the inner pump chamber from the atmosphere without any leakage. The hydrodynamic shaft seal thus only functions fully during operation of the pump. After switching off the pump a stationary seal takes over the task of sealing the shaft gland from the outside. For this a choice can be made between a simple packing gland, a pneumatic system or even a mechanically controlled ring valve of various designs.

The hydrodynamic shaft seal, with few exceptions, is suitable for all pure or solids bearing media which occur in the chemical industry, based materials industry, environmental technology etc.