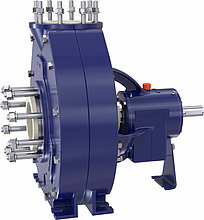

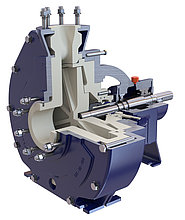

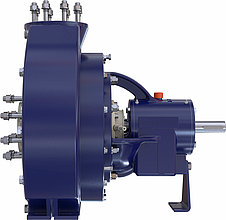

RCNKu

Standardized chemical pump in plastic

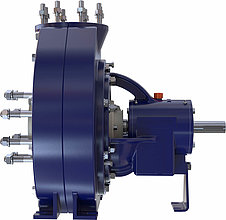

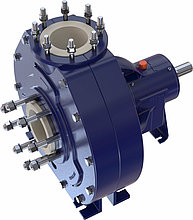

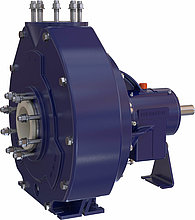

Pumps of the RCNKu and RCFKu type family are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858, ISO 2858 and ISO 5199. With RCFKu, only the overall length is increased by the amount of the spiral width to ensure a free housing passage. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology.

The RCNKu with closed impeller is foreseen for clean liquids and fluids with a small content of solids. The same applies for the RCKu with open impeller design. The RCFKu is able to handle fluids with larger solids.

Design Features

Design

Horizontal cetrifugal pump

Material

Plastics

Size

DN 80 - DN 400

Impeller

closed or free-flow impeller (Type RCFKu)

Delivery rate

Qmax. = 2.500 m3/h

Delivery head

Hmax. = 100 m

Temperature

-40 °C to 190 °C

Nominal pressure

up to 16 bar