Single or double acting mechanical seals are used to seal the shaft gland. Sealing is achieved through axial sliding faces which are pressed against each other by spring force and this prevents them opening when at rest. The stationary part of the mechanical seal usually sits in a housing and the rotating unit on the shaft sleeve. In the sealing gap between the sliding faces a lubricating film is generated by the pumped medium in order to prevent the sliding faces running dry.

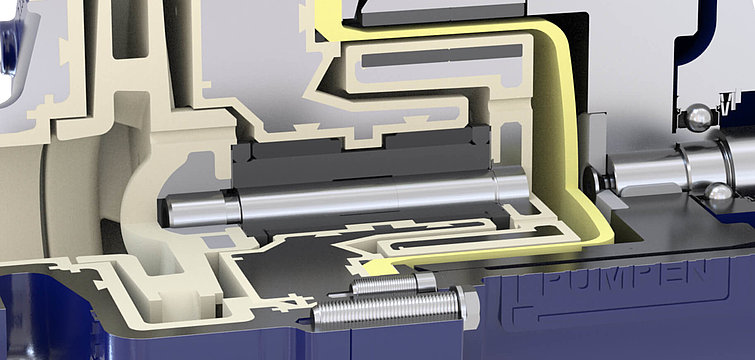

Allpac S

The standard mechanical seal Allpac S can be used universally, even with abrasive media, and is also characterised by its ease of maintenance due to the small number of components. With the double acting mechanical seal two seals are arranged one behind the other so that an additional space occurs between the sliding face of the seals which in turn can be supplied with a pressurised external sealing medium. This ensures that no product can escape into the atmosphere.

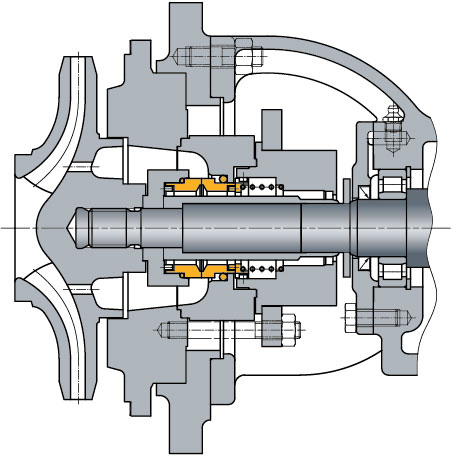

RHETA

RHETA® – designed by RHEINHÜTTE and EASY TO ASSEMBLE. The metal-free mechanical seal is characterized by its high service friendliness. Disassembly is quick and easy from one side. Changing from CS to CST is also uncomplicated and quick. In contrast to conventional mechanical seals, RHETA® consists of innovative materials that ensure a long service life. The seal is completely metal-free so that components cannot corrode. Both the housing and the sealing cover are made of durable plastic, which can handle high temperatures of up to 130°C without any problems. RHETA® also offers the advantage of integrated service flushing so that occasional flushing can be performed easily and cost-effectively.