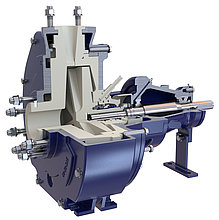

CPDR

Standardized chemical pump in plastic

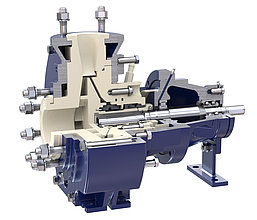

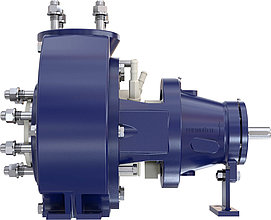

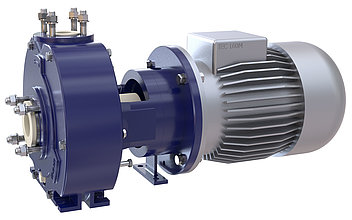

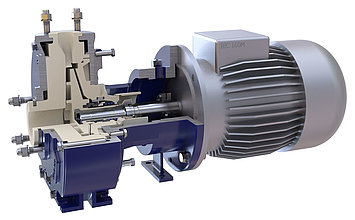

Pumps of the CPDR and CPRF type family are horizontal, single-stage, end-suction, top-discharge centrifugal pumps, standardized to EN 22858 (formerly DIN 24256; ISO 2858 and ISO 5199). The installation length of type CPRF is simply longer about the channel width so that a free passage for the fluid is given. The pumps are used for handling chemically aggressive and/or inflammable liquids within the wide field of chemical processing and environmental technology. The CPDR with open impeller is foreseen for clean liquids and fluids with a small content of solids. The CPRF is able to handle fluids with larger solids. Both types are possible in close-coupled design instead of bearing block.

Design Features

Design

Horizontal cetrifugal pump

Material

Plastics

Size

DN 32 - DN 80

Impeller

open or free-flow impeller (type CPRF)

Delivery rate

Qmax. = 200 m3/h

Delivery head

Hmax. = 100 m

Temperature

-40 °C to 190 °C

Nominal pressure

16 bar