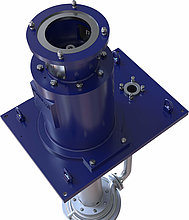

RCEV

Vertical chemical centrifugal pump in metal

Due to its cantilever design and impeller equipped with front and rear blades, the RCEV pump type is highly suitable for handling solids-laden liquids. It is possible to pump up to 30 percent solids with this type of pump, where the type and composition of the solids (hard, soft, light or heavy) plays a important role.

The decision whether to use an open or closed impeller depends heavily on the type of the solids. The RCEV is used to convey mechanically contaminated, corrosive or neutral liquids such as phosphoric acid, highly contaminated sulphur, titanium dioxide slurries, copper dissolution acids as well as liquids that cannot tolerate localised heating by sliding bearings, e.g. concentrated ammonium nitrate solutions, DNT mixtures.

Design Features

Design

Vertical centrifugal pump

Material

Metal

Size

DN 32 - DN 300

Impeller

Closed or open

Delivery rate

Qmax. = 900 m3/h

Delivery head

Hmax. = 85 m

Depth

from 2,00 m

Temperature

-40 °C to 200 °C

Nominal pressure

up to 10 bar